WAM component list

WAM Arm Assembly

The standard four-degree-of-freedom WAM Arm, shown in Figure 1, has four cable-driven joints labeled J1 through J4, and four brushless DC motors labeled M1 through M4. M1 controls the yaw (J1) of the WAM and is located in the base of the WAM. Using Barrett’s patented cable differential, M2 and M3 together control the pitch (J2) and roll (J3) of the WAM, and are contained in the shoulder of the WAM. M4 controls the bend of the “elbow” (J4), and is located just above M2 in the shoulder. Using Barrett’s Puck technology, all motor encoders, power amplifiers, and controllers are located in a single compact package adjacent to each motor, eliminating the need for a controller cabinet and heavy electrical cables.

The standard WAM Arm comes with an internal computer and a blank outer link which is shown attached to the end of the elbow in Figure 1 and shown in full in Figure 2. However, several options such as an external computer and the WAM Wrist (Figure 11) are available to replace these. Regardless of your chosen options, the standard components will be included so that you may always switch between configurations at any time.

The WAM’s internal computer has the following specifications: Mainboard: PFM-540I Processor Type: AMD Geode LX800 x86 @ 500MHz Memory: 1GB (4MB of that is used as a video framebuffer). Hard drive: 8GB, CompactFlash Kernel: Linux 2.6.31.4 patched with Xenomai 2.5.5.2 Distro: Ubuntu 9.10 Expansion Card: PEAK-System PC/104 CAN Card, 2 ports Wireless: Wi-Fi 802.11 b/g (using an external wireless access point, included) Ethernet: 10/100 Base-T

Tool-End Attachments

The WAM™ comes with three endpoint (tool-end) attachments that can be used to change the setup and shape of the WAM™ Arm: the Haptic Ball, the Tool Plate, and the CAN Termination. These items in general will be attached to either the Outer Link (Figure 2) or WAM Wrist (Figure 11). Figure 3 shows the end plates of both the Wrist and Outer Link. The wires and connector coming out of the centers are for running the optional BarrettHand. If using the Outer Link without the Barrett Hand, the wiring can simply be pushed inside the large open cavity. If using the Wrist without the BarrettHand, the wires should be coiled neatly in the small cavity and the Wrist Plug installed to keep the wires from getting pinched.

The Haptic Ball (see Figure 4) can be attached to the end of the Outer Link or the Wrist. It is used to assist in haptic scenes by providing an easy-to-grasp, definable endpoint for the user. Systems are generally shipped with the Haptic Ball pre-installed.

The Tool Plate (see Figure 5) can be installed on the end of the Outer Link, Wrist, or Elbow Plate (if neither the Outer Link nor Wrist modules are installed). It provides a flat base that can be used to attach parts other than the ones designed by Barrett. The Tool Plate has four M6 tapped holes, a 6-mm diameter dowel-pin hole, a quick-connect pin hole and slot, and two holes to connect the CAN Termination. You are free to modify your Tool Plate without voiding your warranty. You can view a datasheet for the tool plate here.

The CAN Termination (see Figure 6) must be used if neither the Outer Link nor the Wrist is attached at the end of the elbow. The CANbus must be terminated at each end with a 120 Ohm resistor to minimize signal reflections. The termination can be attached to either the end plate of the elbow or to the Tool Plate (if attached to the elbow) by the two small holes, which are the same distance apart as the holes on the Termination.

Power Supply

The WAM system is supplied with a 48 VDC power supply. If you require an alternate input voltage, contact Barrett Technology. You may use your own power supply, but improper grounding can cause severe damage to the WAM electronics. If you are concerned that your voltage source may damage the WAM electronics, do not hesitate to contact Barrett for technical guidance.

The Power Supply that ships with the WAM, shown in Figure 7, can be plugged into any regular AC power source. It provides up to 6A of direct current at 48V. This Power Supply switches automatically to local voltage standards (100-120 & 200-240 VAC at 50-60Hz) around the globe and contains built-in surge protection.

Safety Pendants

The WAM Arm system comes with two safety pendants: a control pendant and a display pendant (shown in Figure 8). Both pendants show the present safety status of the WAM Arm, with status lights for the velocity, torque, voltage, and heartbeats of the robot. There is also a 7-segment LED single-character display which shows additional information related to any existing errors. Each pendant has a large mushroom-type emergency stop button, which can be reset (popped up) by rotating the button clockwise for one quarter of a full turn. The control pendant has three additional buttons: Shift, Reset/Idle, and Activate.

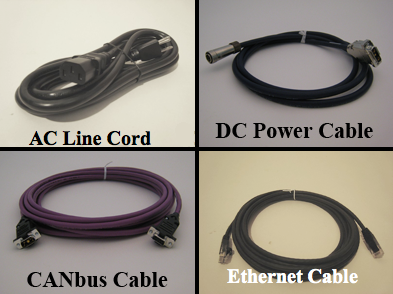

Electrical Cables

All necessary electrical cables are included with the basic WAM System, shown in Figure 9. An AC Line Cord connects the Power Supply to a wall source. A blue DC Power Cable connects the Power Supply or another DC power source to the WAM. If you purchased an external WAM PC, a purple CANbus cable is provided for CAN communication with the WAM. The pendant cables (shown attached to the pendants in Figure 8) connect directly to the WAM. An Ethernet cable is also provided for the option of Ethernet communication with the WAM.

Control Software and Firmware

The WAM’s internal computer has firmware and software that are preloaded before it is shipped.

Included with a copy of the source code in electronic form are:

- Quick Start Guide

- Cable Maintenance Guide

- Inertial Specifications Manual

- Support Resources Reference Sheet

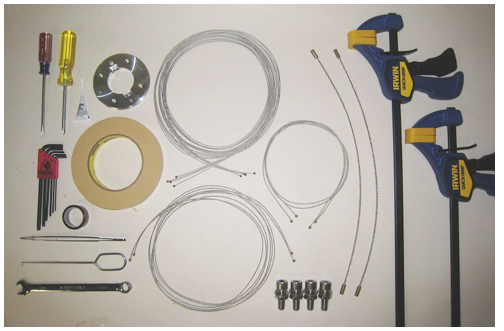

Maintenance Kit

Included in each WAM package is a maintenance kit (shown in Figure 10). The maintenance kit includes the following:

- 1 Tool Plate (normally shipped attached to the Outer Link (or Wrist if purchased))

- 4 M10 Screws, Washers, and Nuts to secure the base

- 1 Set of Metric Hex Wrenches

- 1 Packet of Loctite 222

- 1 10-mm Combination Wrench

- 1 Pair of Tweezers

- 2 Clamps (for clamping the WAM to a table top)

- 1 Roll of 13-mm (1/2”) Masking Tape

- 1 Roll of Kapton Tape

- 1 Slotted Screwdriver

- 1 Phillips-Head Screwdriver

- 1 Push-Pull Hook

- 1 Set Spare Mechanical Cables (Packaged separately from the rest of the Maintenance Kit)

System Options

WAM Wrist

The WAM Wrist module, shown in Figure 11, replaces the outer link of a four-degree-of-freedom WAM, adding joints 5, 6, and 7, for another three degrees of freedom. Mechanical and electrical quick-connect features make it easy to swap between the WAM’s outer link and the Wrist module to convert between 4-DOF and 7-DOF configurations.

In order to minimize the inertial effects of the motors on the host robot arm, the servomotors for joints 5 & 6 are located at the base of the wrist. The final roll joint in the WAM Wrist, motor joint 7, is the only geared axis. At very small scales, such as at joint 7, gears have slightly better performance than cables in terms of compactness.

The WAM Wrist comes with its own separate maintenance kit (shown in Figure 12), which contains:

- 1 Roll 6-mm (¼") wide Masking Tape

- 1 Wrist Tension Tool

- 1 Joint-7 Spanner Tool

- 1 Pull Hook

- 1 Wrist Safety Termination (Packaged separately from the rest of the Maintenance Kit)

External WAM PC

Barrett Technology offers an external PC for advanced control applications that require more processing power or more memory than the WAM’s internal PC can provide. A standard keyboard and mouse, CANbus cable, and 2-m AC line cord are provided for use with the external PC. A monitor (not provided) is needed only during the initial setup of the computer. The external PC has the following specifications:

- Case: Antec P50

- Motherboard: Advantech AIMB-584QG2-00A1E (Socket 1150, Broadwell)

- Processor: Intel Core i3-4330 (Dual-core, 3.5GHz)

- Memory: 8GB DDR3

- Hard Drive: 250GB SSD (Samsumg EVO)

- CAN Card: Dual-port PEAK-System PCI with 500V isolation

- Distro: Ubuntu 14.04.1

- Kernel: 3.14.17 with Xenomai 2.6.4

The following specifications are for Barrett's old external PC offering:

- Case: Lian Li PC-A05FN

- Mainboard: Gigabyte, ATX 1155, MFG-PN: GA-Z68X-UD3H-B3

- Processor Type: Intel i5 SandyBridge Quad-Core 3.3GHz

- Memory: Mushkin, 8GB (2 x 4GB) DDR3

- Hard drive: Western Digital, 500 GB, 7200RPM

- Optical: LITE-ON, DVD Burner

- Kernel: Linux 2.6.32 patched with Xenomai 2.5.5.2

- Distro: Ubuntu 12.04

- Expansion Card: PEAK-System PCI ISO dual-port CAN card

- Ethernet: 10/100/1000 Base-T

Attachments (1)

- WamPC.jpeg (17.6 KB) - added by pb 12 years ago.

Download all attachments as: .zip